Insulated panels form the structural backbone of modern cold storage, clean rooms, modular buildings, and food-processing facilities. Their performance lies at the intersection of thermal engineering, structural design, and fire safety compliance. In South Africa, insulated panel construction must meet the requirements of the South African National Standards (SANS), including SANS 10400 (Building Regulations), SANS 10147 (Refrigeration Systems), and relevant fire safety codes.

Choosing the right core material — Polyurethane Foam (PUF), Polyisocyanurate (PIR), or Expanded Polystyrene (EPS) — determines the system’s energy efficiency, fire performance, and lifecycle cost.

Core Materials in Detail

1. Polyurethane Foam (PUF)

PUF is the industry standard for high-performance insulation.

- Thermal Performance: λ-value of 0.022–0.028 W/m·K, ensuring excellent insulation.

- Applications: Widely used in cold rooms and logistics facilities requiring temperatures down to –40 °C.

- Limitations: Lower fire resistance compared to PIR; requires strict fire protection design.

2. Polyisocyanurate (PIR)

PIR panels are a technical advancement over PUF, offering superior fire safety.

- Fire Resistance: Higher char formation temperature and self-extinguishing properties; compliant with SANS fire codes.

- Durability: Superior dimensional stability at high and low temperatures.

- Applications: Ideal for pharmaceutical storage, clean rooms, and high-risk industrial environments.

3. Expanded Polystyrene (EPS)

EPS provides an economical solution for insulated structures.

- Thermal Performance: λ-value of 0.032–0.038 W/m·K, less efficient than PUF/PIR.

- Advantages: Cost-effective, lightweight, and easy to install.

- Limitations: Poor fire resistance; use restricted in applications requiring high fire safety ratings.

Panel Construction and Engineering Aspects

- Panel Skins: Typically manufactured with pre-painted galvanized steel (PPGI), stainless steel, or aluminum for corrosion resistance.

- Joint Systems: Cam-lock, tongue-and-groove, or hidden fasteners to ensure airtight seals and structural rigidity.

- Vapor Barriers: Critical for sub-zero applications to prevent condensation and frost heave.

- Load Capacity: Panels designed to meet wind loading and structural strength per SANS 10160.

- Fire Compliance: Fire-rated PIR panels can achieve Class 1 or Class B fire ratings, essential for OHS compliance.

Applications in Industry

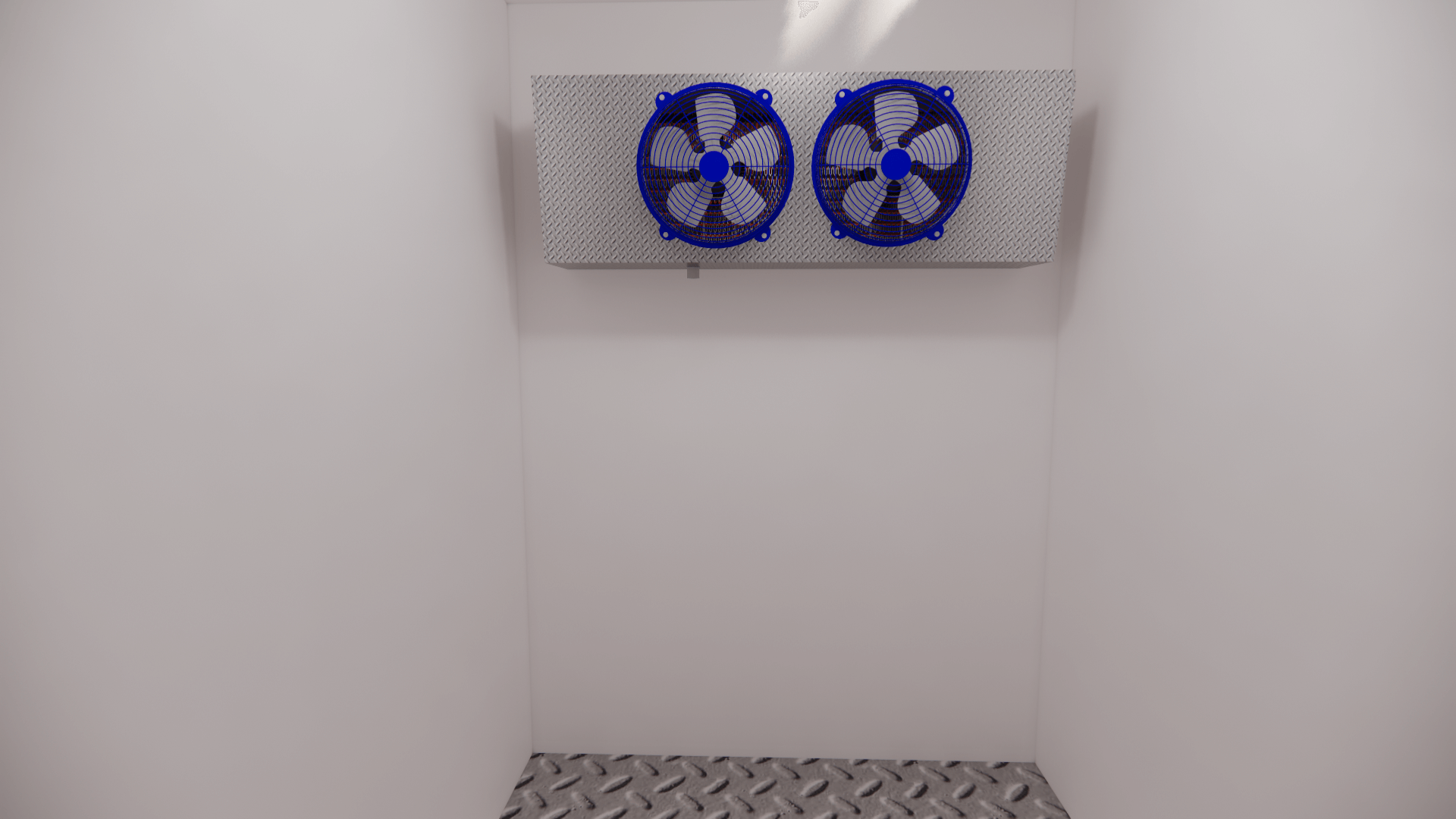

- Cold Storage Warehouses: PUF/PIR panels maintain precise temperature control for perishable goods.

- Pharmaceutical Facilities: PIR panels offer hygienic surfaces and fire safety for controlled environments.

- Food Processing Plants: Smooth, non-porous skins comply with HACCP hygiene standards.

- Modular Construction: EPS panels deliver lightweight, cost-effective solutions for prefabricated structures.

Lifecycle and Compliance

Insulated panel systems must be designed for both performance and durability.

- Maintenance: Regular inspection of joints, sealants, and vapor barriers.

- Fire Safety: Integration with detection, suppression, and compartmentalization systems.

- Sustainability: Panels with recyclable steel skins and CFC-free insulation meet green building standards.

- Compliance: Installation and performance verified through SANS testing and certification.

Conclusion

Insulated panel construction is not just about building walls — it is about engineering environments where temperature stability, fire safety, and compliance are critical. By selecting the right core material (PUF, PIR, or EPS) and adhering to SANS requirements, facilities achieve both operational efficiency and regulatory assurance.

For clients, the benefits are clear:

- Lower energy costs

- Improved safety and hygiene

- Extended asset lifespan

- Full compliance with South African and international standards

In competitive industries where every degree matters, engineered insulated panel systems are the difference between compliance and compromise.